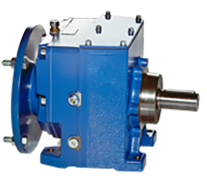

In-Line Gear Reducers

In-Line Gear Reducers reduce the speed, torque, or direction of an input shaft using gear ratios that are aligned along the same centerline. They transmit the torque in the same direction as the motor. The primary advantage of inline gear reducers is their ability to maintain control in applications that involve high rotational speeds.

HVH Industrial works with the specialized engineering teams of manufacturers to meet our customer's requirements and the highest quality standards.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

In Line Gear Reducers

Manufacturers

What are Inline Gear Reducers

Inline gear reducers are an essential component of many mechanical systems as they are used to reduce the speed of an input shaft and increase the torque output. Inline gear reducers are composed of two sets of internal gears. The first set, known as the input gears, is connected to the motor or engine and spins at a relatively high speed. The second set, known as the output gears, is connected to the load and spins at a slower speed. An inline gearbox's input and output shafts have the same orientation. In contrast to other gearbox configurations in which the gearbox output shaft may be at right angles to the input shaft, an inline gearbox transmits torque in the same direction as the motor.

Types of Inline Gear Reducers

There are several different types of inline gear reducers, but the most important two types are inline helical and inline planetary.

Helical Gear Reducers

Helical gear reducers are a type of inline gear reducer that uses helical gears to transmit power from the input shaft to the output shaft. The helical gears have teeth that are cut at an angle to the face of the gear, which helps to reduce noise and vibration. Helical gear reducers are among the most commonly used gear reducers in various applications.

Planetary Gear Reducers

Planetary gear reducers, also known as epicyclic gear reducers, are a type of inline gear reducer that consists of central sun gear, planet gears, and outer ring gear. They are known for their compact design, high torque capacity, and high efficiency. Planetary gear reducers can achieve high gear ratios in a single stage, making them suitable for various applications that require high torque and compact design.

Benefits of Using Inline Gear Reducers

One of the primary benefits of using an inline gear reducer is increased torque output. By reducing the speed of the input shaft, the gearbox can increase the torque output of the system. This can be particularly useful in applications where high torque is required, such as in conveyor systems.

Another advantage of using inline gear reducers is improved efficiency. These gearboxes can help to reduce the load on the motor, which can improve the overall efficiency of the system. This can result in energy savings and lower operating costs, making inline gear reducers a cost-effective solution for many mechanical systems.

Inline gear reducers are also known for their reliability and durability. These gearboxes are designed to handle high loads and withstand harsh operating conditions, making them an ideal choice for many industrial applications. With proper maintenance, inline gear reducers can provide many years of trouble-free service.

Applications of Inline Gear Reducers

Inline gear reducers are used in a wide variety of applications, including conveyor systems, food processing equipment, and factory automation systems. In conveyor systems, these gearboxes are used to increase the torque output and reduce the load on the motor, which can improve efficiency and reduce operating costs.

In food processing equipment, inline gear reducers are used to power mixers, grinders, and other machinery. These gearboxes are designed to handle the high loads and harsh operating conditions that are common in the food processing industry, making them an ideal choice for this application.

In factory automation systems, inline gear reducers are used to power robotic arms, conveyor systems, and other machinery. These gearboxes are designed to handle the high loads and fast operating speeds that are required in this industry, making them an essential component of many automation systems.

Inline gear reducers are an essential component of many mechanical systems. They offer many benefits, including increased torque output, improved efficiency, and reliability. These gearboxes are used in a wide variety of applications, including conveyor systems, food processing equipment, and factory automation systems.

If you're looking to improve the efficiency of your mechanical systems, consider using an inline gear reducer. With proper maintenance, these gearboxes can provide many years of trouble-free service and help reduce operating costs.